Building a rocket engine

"I'm Martin and I'm part of the team that participated in the development of the innovative Hodor valve, designed for precise dosing of fuel in rocket engines. After a successful static ignition on the test site, I'm convinced that this valve will take our possibilities in space research one step further.

Together with the CTU Space Research team, we tested the Hodor valve on a rocket engine, including tests with water at a pressure of 50 bar. During the first static ignition of the hybrid rocket engine, we controlled the main supply of the oxidizer (nitrous oxide, 60 bar) to the combustion chamber. We only had one go at the ignition, but the valve worked flawlessly and we achieved a 2.4s ignition.

We know from other tests that Hodor works excellently even in a severely hypothermic state.

So far, the last test took place in Bratonice, when after 17 hours of hard work we achieved a successful hot-fire, although it was not without challenges. Our engine sustained the required thrust for more than 7 seconds!"

Don't miss your chance for an amazing future.

Be like Martin - decide for FEL today!

I am part of the future of e-mobility

"I am Poli and I am a follow-up student at Faculty of Electrical Engineering, majoring in Electrical Machines. I want to introduce you to my two projects. The first one I worked on was the design and testing of a power semiconductor converter intended for use in an electric scooter. Because the future of e-mobility is simply too great to miss!

I worked on this project as part of my bachelor thesis.

My second project that I am currently working on involves modeling and software design for heat distribution in electrical machines. My research will find its application in optimizing the performance and reliability of electrical equipment.

You too can work on your own projects in this field of endless possibilities. So join in!"

The door to a world of unlimited possibilities is opening.

Be like Poli - decide for FEL today!

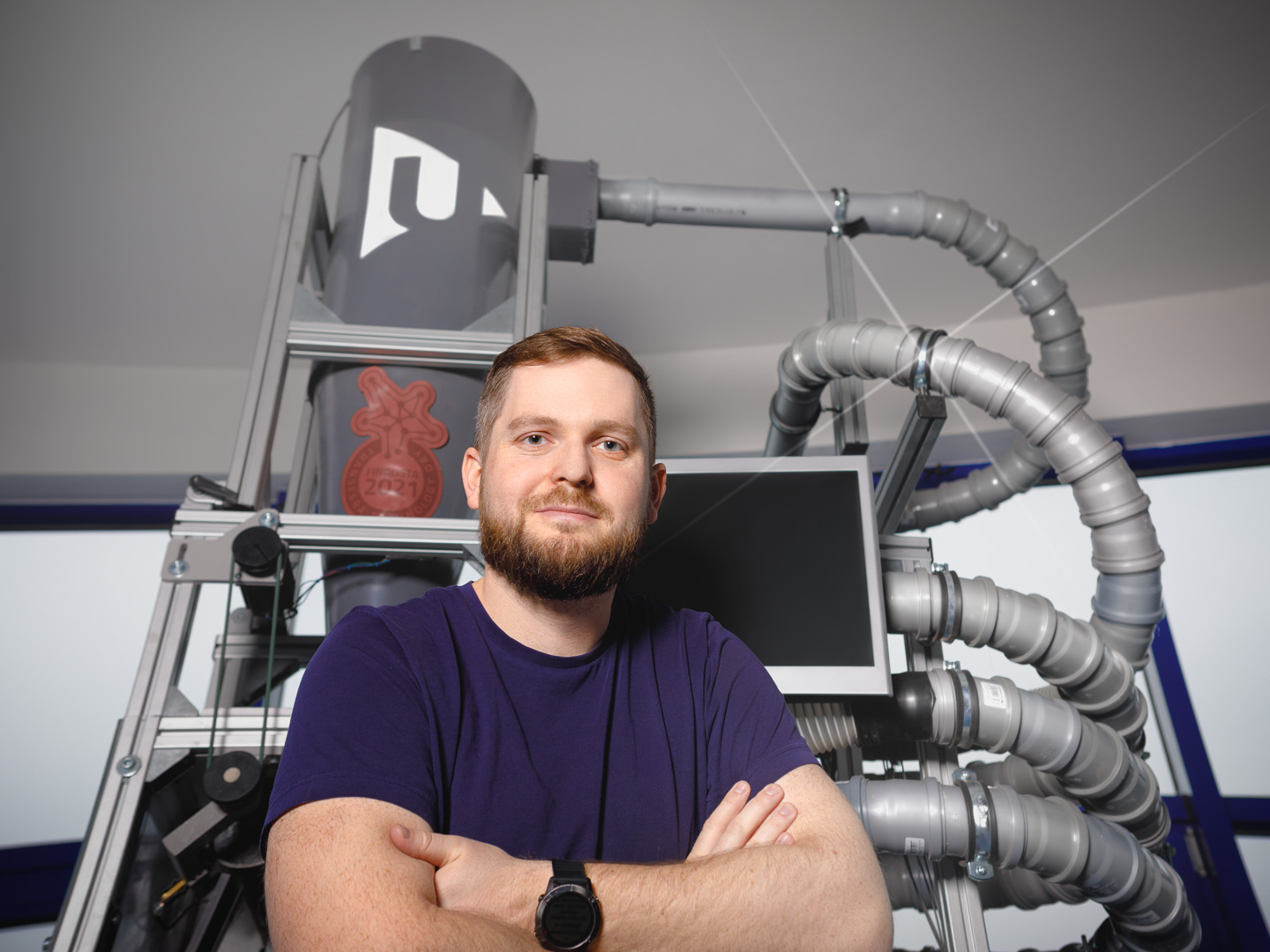

I'm changing the rules for a cleaner future

It was originally intended only for recycling plastics, but now, as part of cooperation with various companies, we also focus on agricultural crops. I really enjoy working in a team and working on such an interesting topic. And to add a little "wow" factor: 62 million tons of plastic were produced in 2018, with only 44 % recycled.

No time to waste. At FEE, we have found part of the solution to a global problem!"

Participate in the future of our planet.

Be like Jirka - decide for FEL today!

Our socks will tell you in time to put your feet up!

"I am Misa, a doctoral student at the Faculty of Electrical Engineering UWB.

During my Bachelor's studies, I became interested in smart textiles, and in my final thesis, I was involved in testing smart socks for monitoring swelling. Hybrid conductive threads are woven into the socks. During swelling, the conductive paths are stretched, and their electrical parameters change, which can be monitored using an evaluation unit. This will give you timely and accurate information about the condition of your feet.

As this innovation shows, smart textiles go beyond sewing, knitting, and embroidery. Skilled programmers or PCB designers and evaluation equipment are also needed.

So when you wear our socks, you will not only be stylish but also have a controlled view of your health!"

Get involved in innovation to improve safety and well-being.

Be like Misa - decide for FEL today!

I built an electric mountainboard with a classmate

"I'm Adam, and in the second year of my Bachelor's degree, I participated in the construction of an electric mountainboard as part of the VPP optional subject.

What does a mountainboard even mean? It is simply a means of transportation similar to a skateboard or longboard, which is intended for off-road use. In contrast to the hard plastic wheels, the mountainboard is equipped with large inflatable wheels with a terrain pattern, and the whole board is generally very soft to cushion the unevenness of any surface as well as possible. The result is a board created for the terrain, but it can also be used, for example, on asphalt. In addition to two BLDC motors with a total output of 5.6 kW, the mountainboard has a battery made of li-ion cells and a two-channel converter that drives the mentioned two motors.

The mountainboard is controlled by a remote control, which the rider holds in one hand, thus having full control over its speed. Turning takes place as standard with a skateboard or longboard, i.e. by tilting. The maximum speed is rather difficult to measure because from a certain speed, due to the softness of the board, the mountainboard begins to oscillate uncomfortably and becomes difficult to control, however, it is not a problem to go 40-50 km/h or more. If we wanted even more speed, all we had to do was change the belt transmission between the motor and the wheel. The range is also difficult to determine and depends mainly on the driving style and tire inflation. However, the maximum range is around 20-30 km."

Build your own e-mobile gadget with us.

Be like Adam - decide for FEL today!

Programming rock'n'roll

"I'm Jakub and I'm a Bachelor's student at the Faculty of Electrical Engineering in Pilsen. I specialize in electronics, robotics, and computer modeling at the KEP department. Studying here gave me a wonderful opportunity to combine my two hobbies – robotics and music. I am involved in the creation of a rock robot band, which we call KapFELa. This job gives me a unique opportunity to improve my skills in the field of electronics while solving practical problems. Currently, as part of my Bachelor's thesis, I am working on a robotic drum project in our robotic band, which is the last, key element to complete this innovative band."

"I'm Honza, and as part of my Bachelor's studies at FEE in Pilsen, I threw myself into an interesting robotic band project at the Department of Electrical Engineering and Computer Modeling (KEP). From the very beginning, we set ourselves the goal of creating a band that would be able to play independently and use real instruments. It was an ideal opportunity for me to combine theoretical knowledge from my bachelor's studies with practical experience. The project brought me practically closer to electronics, programming, and 3D modeling, which often made my studies easier. As a final project, I independently formed a significant part of the future band and that robotic bass guitar. I appreciate that I had a team of great people with whom I could consult at any time. Starting projects with a team and with practical experience is just great!"

FEE in Pilsen - the right choice for studies full of challenges.

Be like Jakub or Honza - decide for FEL today!

I am programming a robot

"My name is Vojta and I'm in the second year of my bachelor's studies. As part of my studies, I also focus on robotic systems. Currently, I'm working on one of the projects in the Industrial Robotics Laboratory, which focuses on robot programming. Specifically, I'm designing and building a hexapod robotic spider. Since it's my own design, I have to deal with both the mechanical and electrical aspects of the robot. Finally, I will create a program in the microprocessor to control the entire robot."

Robotics is the future.

Be like Vojta - decide for FEL today!